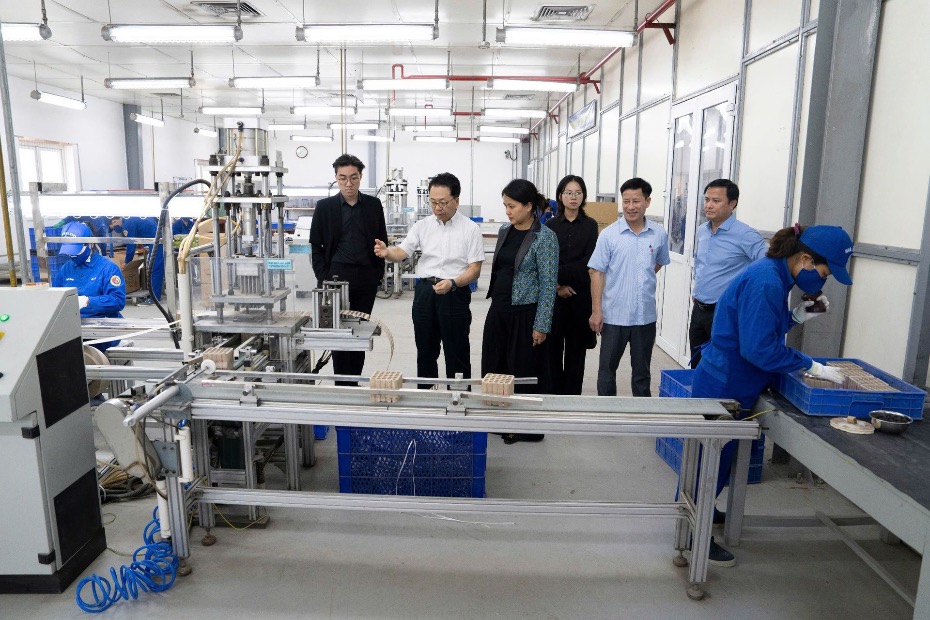

MES (Manufacturing Execution System) is a software system designed to manage and control manufacturing operations within a factory or manufacturing enterprise.

MES Implementation Services represent a strategic investment that delivers sustainable value for manufacturing enterprises. By digitalizing and integrating production processes, MES not only helps businesses improve operational efficiency and reduce waste, but also enables the establishment of a transparent and flexible management system. This is a critical step for enterprises to build competitive advantages, enhance manufacturing capabilities, and be ready to accelerate growth in the digital era.

MES Software (Manufacturing Execution System)

MES is a specialized application designed and “tailor-made” to meet specific manufacturing characteristics, enabling optimized management and control of production processes. The software is typically integrated with other enterprise systems such as ERP (Enterprise Resource Planning) and PLCs (Programmable Logic Controllers) to provide real-time information and optimize manufacturing operations.

Benefits of MES Implementation

1. Real-time Production Monitoring:

Provides a comprehensive view of production status, enabling managers to easily track progress, machine performance (OEE), and product quality.

2. Production Process Optimization:

Automates task allocation, production scheduling, and material management, helping reduce downtime and increase productivity.

3. Improved Product Quality:

Closely monitors and controls technical parameters throughout the production process, allowing early detection and prevention of defects.

4. Traceability Management:

Records complete production data from raw materials to finished products, meeting quality standards and customer requirements.

5. Integration with Other Systems:

Seamlessly integrates with ERP, WMS, and other systems to create a unified and consistent information flow across the enterprise.