1. ISO Training and Consulting

Objectives of ISO Training and Consulting

- Guiding enterprises to thoroughly understand ISO standards (ISO 9001, ISO 14001, ISO 45001, ISO 22000, etc.).

- Supporting the establishment and effective operation of management systems in compliance with ISO standards.

- Enhancing internal capabilities to sustain and continuously improve ISO management systems in the long term.

- Assisting organizations in achieving ISO certification from reputable certification bodies.

Benefits of Implementing ISO Standards

- Standardizing processes and reducing operational risks.

- Enhancing credibility with customers, partners, and regulatory authorities.

- Improving management effectiveness and operational efficiency.

- Establishing a solid foundation for continuous improvement and digital transformation.

2. 5S & Kaizen Consulting and Training

Objectives of 5S & Kaizen Consulting and Training

- Enhancing employees’ awareness, discipline, and positive working attitudes.

- Creating a safe, organized, clean, and efficient working environment.

- Establishing a foundation for a continuous improvement culture (Kaizen), gradually improving productivity and quality.

- Supporting enterprises in developing toward Lean operations, process standardization, and digital transformation.

Benefits of Implementation

- A safer, cleaner, and more efficient working environment.

- Employees demonstrate self-discipline and a continuous improvement mindset.

- Reduced waste and errors, leading to higher productivity.

- Strengthened employee engagement and promoted a strong corporate culture.

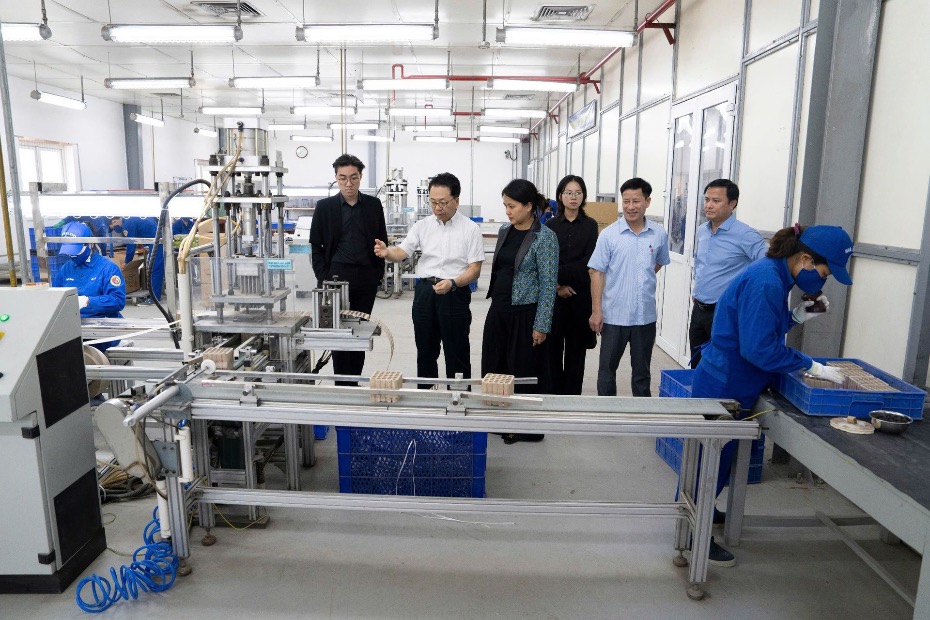

3. Lean Manufacturing Consulting and Training

Objectives of Lean Manufacturing Consulting and Training

- Eliminating waste throughout the entire production process.

- Optimizing the value stream to enhance operational efficiency.

- Reducing costs and shortening lead times.

- Increasing productivity and quality, while improving customer satisfaction.

- Establishing a foundation for a culture of continuous improvement within the organization.

Scope of Application

- Implemented across manufacturing plants, workshops, warehouses, and internal logistics.

- Can be integrated with other management systems such as ISO, 5S, TPM, Kaizen, and Digital Transformation.

- Applicable to various manufacturing industries: mechanical, electronics, textiles, food, plastics, and more.